At Dotmar Injection Moulding, we specialise in transforming ideas into high-quality, precision-engineered plastic components.

With decades of industry expertise, we partner with businesses to innovate, design, and manufacture exceptional products across industries such as Automotive, Food & Beverage, Pharmaceuticals, Consumer Goods, and more.

Our ISO 9001 certification underpins our quality management system, ensuring consistent reliability in every product we deliver.

Our capabilities

Product Design and Tooling

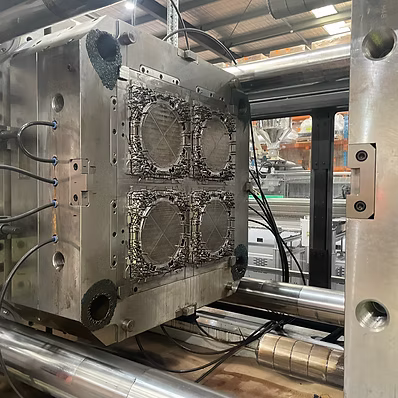

Fully Equipped Injection Moulding Facility

Product Assembly and Value Added Services

Industries we service

Building & construction

Outdoor & Garden

Pool & Spa

Safety

Consumables

Food & Beverage

Pharmaceuticals

Auto

Agriculture

Boat & Marine

Your Product, our commitment

Uncompromising Quality Assurance

- ISO 9001 certified with rigorous quality control processes

- In-house testing facilities for comprehensive material and product inspections

- Detailed pre-production sample testing and post-production audits

Expert Guidance and End-to-End Support

- Dedicated project management team providing ongoing support throughout the process

- Consultation on material selection, product design, and process refinement

- Clear communication and rapid response to customer inquiries

Reliability and On-Time Delivery

- Robust production planning, real-time project tracking, and efficient logistics management

- Ability to meet tight deadlines and handle complex production requirements

About Dotmar

With a legacy of over 50 years in the plastics industry, Dotmar is the largest distributor of semi-finished engineering thermoplastics and conveyor components throughout Australia and New Zealand.

Our eight machining centres, alongside our full-service injection moulding facility (Dotmar Injection Moulding), combined with a team of skilled engineers and industry experts, enable us to bring your ideas to life—whether it’s a single prototype or large-scale production runs.

Dotmar partners with some of the world’s most trusted and respected companies and organisations, including the Australian and New Zealand Defence Forces, Coca-Cola, Rio Tinto, Asahi Breweries, Arnott’s Group, BHP Billiton, and many more.